|

|

|

Photographs (left to right): Water lily, Adirondacks, New York; Seagull, Florida; Bullock's Oriole, California

|

Seven Turtles Wampum Belt |

Making Wampum BeltsRichard D. Hamell |

My interest in bead weaving began in my childhood with seed-beading on a small six to eight inch loom using standard sewing thread. Eight years ago I made my first ‘wampum’ belt using plastic pony beads with artificial sinew. Not satisfied completely with the overall appearance I became the search for wampum beads. That quest lead me to contact Tara Prindle, who made pseudo-wampum using a special mixture of acrylic clays.

The second step in making wampum belts was the search for the materials to make a suitable loom. A company such as Lowe’s would have the necessary wood and accessories to build your loom. The looms I have built are four-foot long. The width of the board depends on the width dimension of the belt you want to create. Therefore, I have two looms, one a ten-inch board and the smaller one, six inches wide. Over the five years I have been making replica belts I have finalized the loom design as illustrated below. I have mounted the end brackets (metal shelving L-brackets) onto a wood-wing that is movable on track lighting rails (one track is cut in two to be the slide for the take-up loom rods. The width of the belt can be adjusted by inserting dolling of needed lengths and spacing the L-brackets according. The dolling rods are cut about every three-eights of an inch. The cut is about three-quarters the way around and about three-eights of an inch deep. These grooves will hold the leather weave. To secure the leather, wrap it completely around the dolling and wedge it in the same groove. Wing-nuts are used to make the adjusts to the rail-system easy.

|

|

Figure 1 |

Figure 2 |

Four-Foot By Six Inch Loam |

Four-Foot By Ten Inch Loam |

If the belt to be made is longer than the length-spacing of the brackets, add a third bracket that will be the take-up reel (see Figure 2). The take-up reel is mounted to be free-turning and when needed to be tightened, it has a peg opening through which a small diameter dolling can be inserted to keep it from unreeling. Approximate cost for the loom is around $50.00. You can save about half the cost by not using the electrical lighting track and just screw the furring strips (two 20"-24" into the loom board to have a permanent upright for the doweling.

Material List

Pine loom board: 1"x8"x 48" - $11.94 each

Pine loom board: 1"x10"x48" - $13.94 each

Bracelet wing board: 1"x3"x48" (cut into 4 - 6" lengths): $1.17 each

Doweling (need two), 1.25"x48" - $2.64 each

Lighting track (3), 48" - $8.13 each

12 Carriage bolts 5/16"X 1 1/4"with nuts 20/bag) for loom rail - $5.24

20 Flat washers for the above (25 pack) - $8.25

4 wing nuts (20 pack) - $1.21

4 Shelving Brackets 14" - $1.86 each

12 1/2"wood screws for brackets - (0.04 each)

4 flathead wood-deck screws with lock washers for doweling (bag 25)- $5.68

Beads and Materials

|

Simulated wampum beads | see Wandering Bull and Crazy Crow as a possible supplier |

|

|

Artificial Sinew | http://www.jas-townsend.com/index.php Jas Townsend & Son, Inc. 133 North First Street PO Box 415 Pierceton, IN 46562 800.338.1665 |

1/2# Spool - $7.50 1/4# Spool - $5.00 |

|

Angled Scissors | JoAnn Fabrics | $25.00 |

|

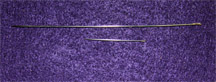

5" Needles Assorted Sizes |

JoAnn Fabrics | $8.84/4 $2.50 |

|

Beading Tray | Shop around for a better board one with parellel grooves which can hold 20 beads in a line. Having a friend with a rotor helps. Amazon.com And Hobby Shops |

$? |

|

Branding Iron & Temperature Controller (not shown) Monogrammed branding tip with name |

Hexacon http://www.hexaconelectric.com/CONTACTUS/tabid/61/Default.aspx 908.245.6200 |

$350.00 |

|

X-Acto Knife box of 100 blades |

Amazon and art stores | $5.50 $21.00 |

|

36" X 24" Alvin self-healing cutting mat | Alvin and Dahle are two brands Art Supplies Stores, Amazon |

$35.00 |

|

Deer Hide |

Find a Vendor near you or Native Leathers 6360 Transit Rd Depew NY 716-536-7183 |

average $50.00 - $60.00 per hide |

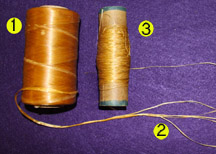

The artificial sinew line(1) can be separated into 5 separate strands (2) which are of appropriate size for weaving the beads. I cut the line into 4-foot length and separate the strands which are then wrapped onto a spool (3). The angled scissors are useful in trimming high spots on the rawhide strands once they are strung on the loom.